Insights from the FII/BSLC Survey of International Tall Wood Buildings

Insights from the FII/BSLC Survey of International Tall Wood Buildings

In the fall of 2013, Forestry Innovation Investment and the Binational Softwood Lumber Council commissioned Perkins+Will to conduct a survey of completed Tall Wood buildings from around the world, and share the lessons learned by others with those contemplating similar projects in North America. The study was published in the spring of 2014, and SABMag took the opportunity to speak with the lead author, Rebecca Holt of Perkins+Will in Vancouver.

By Rebecca Holt of Perkins+Will in Vancouver.

<SABMag: I notice that not all of the buildings in the study are ‘tall’ – in fact some have as few as five storeys. Can you explain the selection criteria.

>RH: Our definition of ‘tall’ was a building that exceeded the allowable height limit of wood construction in the local building code at the time of approval. In most cases that was between four and five storeys. We also understood that the development and design community had expressed reservations with a number of issues including structural stability, construction tolerances, moisture protection or acoustics across building types. The goal of the Survey was to represent the range of construction types, including mass timber panel systems, post and beam and hybrid systems across building typologies, to address these concerns.

<SABMag : Even with the progress being made here in North America, we don’t seem to have developed the ‘wood culture’ that appears to exist in Europe – at least not yet.

>RH: Yes, I agree in reference to solid timber construction. This will come as we gain experience I think, but one of the biggest differences right now is product availability. In Europe there are multiple sources of CLT and other products and each comes with a considerable amount of technical expertise that manufacturers and installers have acquired over time.

<SABMag: You have identified the need to commit to wood as a structural system from the inception of the project. Is this because the properties and performance of wood systems are quite different from those of other structural materials?

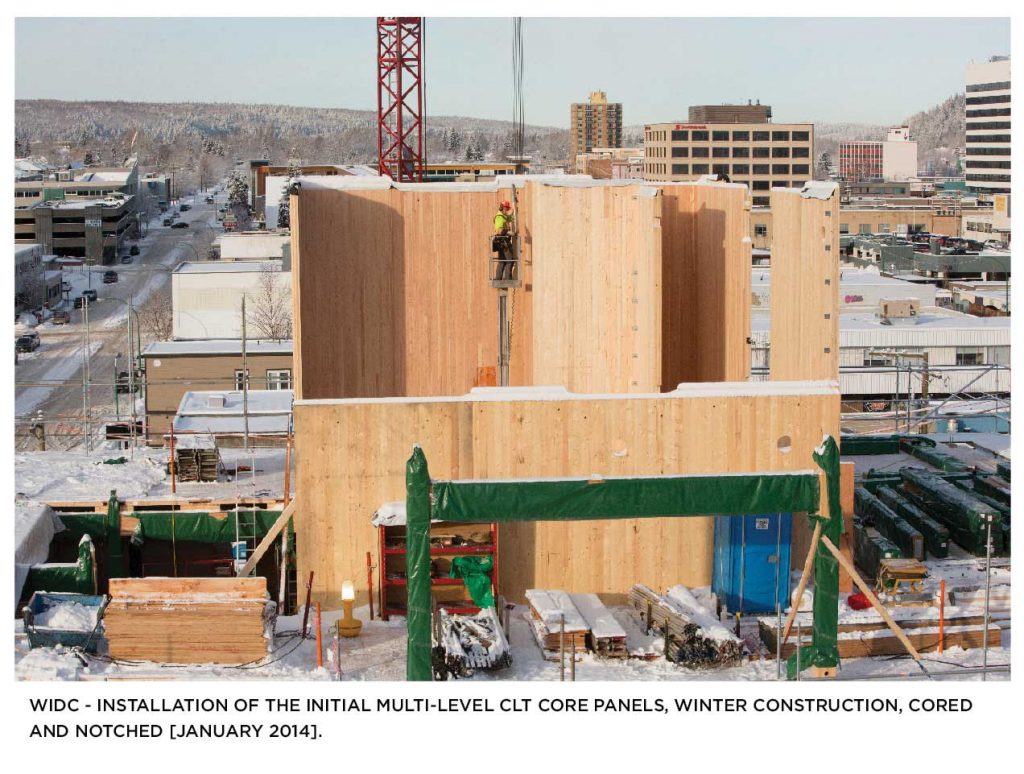

>RH: We didn’t address the differences between wood, concrete and steel structural systems specifically, but what we did establish was the need not only for a collaborative team approach, but for the development and incorporation of appropriate details in the construction documents that will capitalize on the speed and precision that is possible when using prefabricated wood components.

<SABMag: Is the use of prefabrication related to the high performance nature of the buildings you researched?

>RH: Yes, prefabrication can ensure very precise cut and fit of elements which helps to create air-tight envelopes and support other essential components of energy efficient construction. For those buildings that had operational data available, the shop fabrication of the envelope appeared to offer the greatest performance advantage. Being a poor conductor of heat, wood reduced the negative effects of thermal bridging. As a material, it seems to be highly compatible with high performance energy standards such as Passive House.

However, it should be noted that prefabrication was not limited to the wood components. Where we looked at buildings with concrete cores, and other concrete components, those that benefited the most were the ones that used prefabricated concrete panels. This was not just a question of precision, but also of speed and the elimination of wet trades on site.

<SABMag: That prompts a question about acoustics. If you eliminate wet trades, and with them concrete toppings, does this compromise acoustic performance?

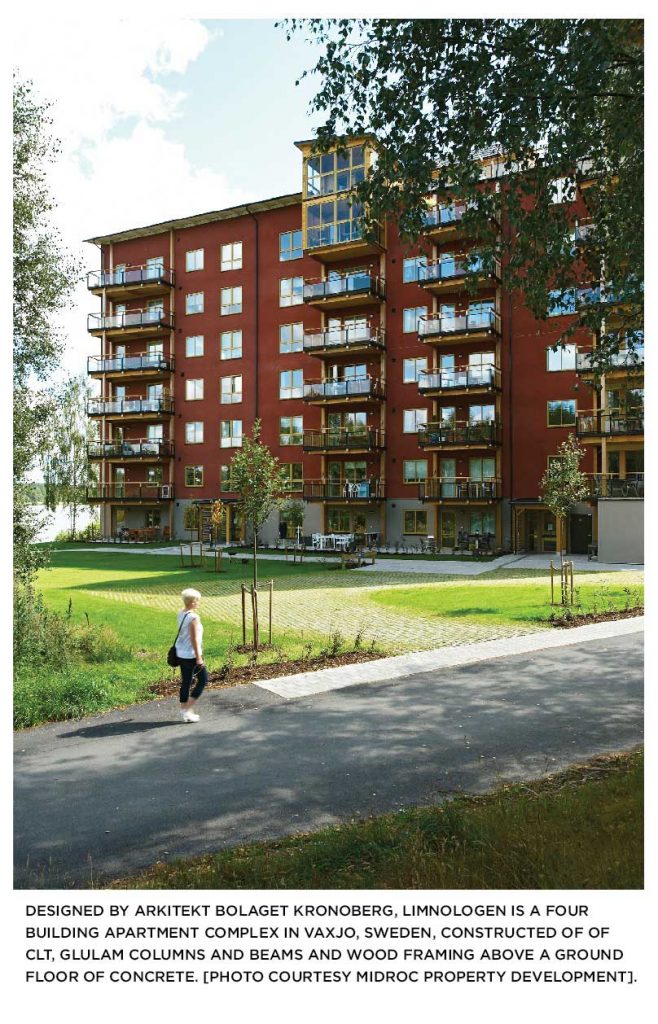

>RH: There seems to be a lot still to learn about acoustic and moisture issues, so there is a balance to be struck between the desire to eliminate wet trades and the desire to achieve acoustic separation. We did see one or two projects that used a sand layer as an acoustic barrier, and others that focused on separating or decoupling floor and wall assemblies to address transfer of sound between spaces; both appear to be successful. It is worth noting that for Limnologen, a CLT project completed in Sweden in July 2009, which does not include a concrete topping on the floors, a post-occupancy survey recorded only one complaint about acoustic performance.

<SABMag: You raise the issue of moisture protection during construction, Did you find any consensus on this subject?

>RH: There appears to be no single approach to the issue of weather protection. In Sweden buildings are typically protected with a rising tent system, that may have as much to do with creating a better working environment as it has to do with protecting wood components from the weather. In the UK where there are a great number of CLT projects including the Murray Grove and Bridport House apartment towers, and several large schools, they don’t seem to take such a conservative approach. Anecdotally we understand that engineered wood products such as CLT and LVL can handle a fair amount of exposure to weather.

<SABMag: It seems as if architects and engineers are prepared to take on the challenge of building bigger in wood, but what about the owners, occupants and municipal officials?

>RH: Perhaps the most comprehensive response came from the Limnologen project I mentioned previously, where we were able to interview owner/occupiers of one suite, as well as representatives from the City of Vaxjo. The owners were intensely proud of their building and considered it to have been a good investment. They spoke specifically about the sense of well-being and the quality of their space.

For their part, the city of Vaxjo has some very innovative and supportive policies in place. They have been monitoring the Limnologen project since its completion and have committed to building almost exclusively in wood, not just for residential buildings but also institutional buildings for universities and hospitals. Wood is an important component of their municipal carbon neutral policy.

<SABMag: It would seem from the survey that wood is a viable and desirable alternative to steel or concrete, even in larger buildings. Is that a fair conclusion to draw?

>RH: Yes, I would definitely agree with that. However, it was made clear by everyone we spoke to that they are advocates of using wood in the right context, where the material makes sense. Also, that designing large wood buildings requires a holistic and collaborative approach that engages all the stakeholders from the outset. This was identified as a priority, not just by the design teams and owners, but the authorities having jurisdiction as well. Everyone needs to have the opportunity to contribute their expertise, because everything needs to be planned so carefully. This is particularly true right now, when most people are at the very steep end of the learning curve.

<SABMag: Thanks for sharing your insights. I am sure they will be helpful in raising the comfort level for those contemplating a large- scale project in wood.

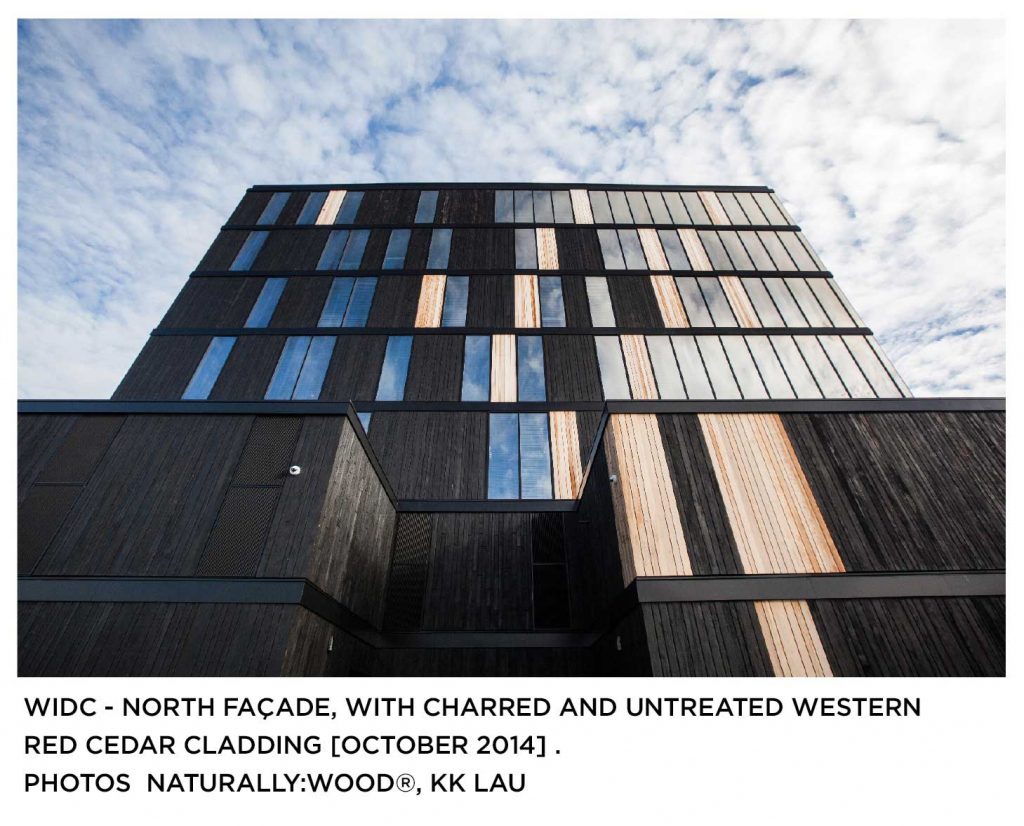

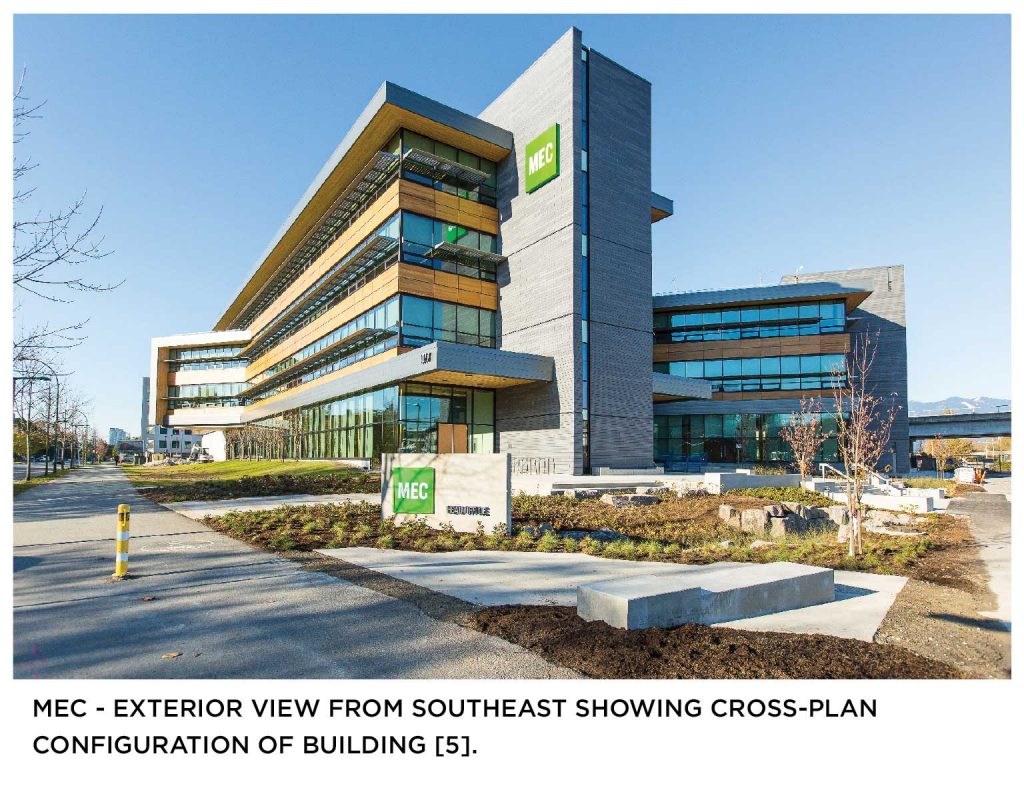

Article compiled by SABMag Editor Jim Taggart, from material supplied by naturally:wood® [WIDC] and BC Wood Works [MEC]. Rebecca Holt, M.Urb, LEED AP BD+C, ND, is a Sustainable Building Advisor and senior researcher with Perkins+Will’s Research team in Vancouver.