Visit the Directory of Products and Services for Sustainable High-Performance Building

LEED categories noted for the products listed in the following pages are intended to show how these products can potentially help a project earn LEED v4 points.

Companies listed in bold have 1/8-page listings containing more information, and are linked to their websites from the online version of the Directory.

PRODUCT DIRECTORY

St. Benedict Church

Achieving net-zero-energy sets the bar high for community buildings

By Michael Nicholas-Schmidt and Roberto Chiotti

This new suburban church in Milton ON was designed in response to the 2015 Papal Encyclical Laudato si’, On Care for Our Common Home; a call to action to address the ecological crisis facing all life on earth. The document affirms that issues of economics, social justice, and ecology are inseparable.

Thus, the parish wanted to create a welcoming facility, not only for their own faith community but also for the broader community they serve. The building program is organized to embrace a central entrance courtyard and gathering space. Both the worship space and social hall have expansive glazing to ensure that the community activities taking place within are visible to all.

In terms of energy use and environmental impact, the parish established goals for the project of net-zero operating energy with net-zero carbon emissions and a substantial reduction in the embodied carbon of the completed building. To that end, the building envelope was designed with R-60 effective for the roof, R-35 effective for the walls, R-15 effective for the slab on grade and buried ductwork, and R-8 for exterior glazing. Careful consideration was given to the elimination of thermal bridging; superior air tightness and the incorporation of a 95 KW Solar photovoltaic system.

Another goal was to source and specify local materials and labor to better support the regional economy; and to use natural materials wherever possible. Ninety-five percent of all materials and labour were regionally sourced; including structural wood components for the roof, locally quarried stone, and locally produced steel roofing.

Project Credits

- Architect Larkin Architect Limited

- Owner/Developer The Diocese of Hamilton

- General Contractor Melloul-Blamey

- Landscape Architect Vertech Design

- Civil Engineer Basetech Consulting

- Electrical Engineer Rombald Inc

- Mechanical engineer Zon Engineering

- Structural Engineer WSP

- Commissioning Agent HTS

- Energy Modelling Hadlock Consulting

- Renewable Energy Zon Engineering

- Photos Scott Norsworthy

Project performance

- Energy intensity (building and process energy) = 65.9KWh/m2/year

- Energy intensity reduction relative to reference building under MNECB

- 2015 as modified by SB-10 = 31%

- Reduction in water consumption relative to reference building

- under LEED = 50%

- Recycled material content by value = 4%

- Regional materials (800km radius) by value = 95%

- Construction waste diverted from landfill = 80%

Michael Nicholas-Schmidt, BES, M.ARCH, OAA, MRAIC and Roberto Chiotti, BES, BARCH, MTS, OAA, FRAIC, LEED™ AP are Principal and Founding Principal at Larkin Architect Limited.

SUBSCRIBE TO THE DIGITAL OR PRINT ISSUE OF SABMAGAZINE FOR THE FULL VERSION OF THIS ARTICLE.

Hockey, Peacekeeping and HFO

Carbon reduction innovation in closed-cell foam insulation

By Rocky Boyer

Canada has been a leader in two of the most important and influential global topics for the past 60 years—Peacekeeping and Hockey. While these two subjects are still important to its identity, Canada is now emerging as a world leader in the sustainability, climate change, and resiliency movement.

Some key facts about Canada is that it has the second largest land mass in the world (9.9 million m2), is ranked as one of the coldest countries in the world, but what may come as a surprise is that Canada accounts for only 2.0% of annual fossil fuel emissions (Figure 1).

As Canadians, we are blessed with approximately 900 million acres of forests with each 2.5 acres of forest absorbing six tons of CO2 per year. While the country benefits from the natural carbon sequestration systems, Canada’s government and its citizens are working hard to reduce emissions even further. One of these major carbon reducing actions falls within the construction industry and, more specifically, thermal insulation.

Thermal insulation, whether traditional or high performing, all require energy and fuel to extract, produce and transport. Only when this insulation is installed in a thermal application (not acoustic or aesthetic) can the energy and carbon savings occur. I define traditional insulation as insulation that uses trapped air (batt insulation) for its thermal performance, and high-performance insulation as insulation that uses trapped gas (sprayed polyurethane foam, board stock foam) for its performance in conjunction with an air, or air/vapour retarder system.I hear all the time, although not technically correct, that “insulation saves energy!” Not all insulation reduces energy consumption when you consider products such as acoustic panels or aesthetic tiles.

Insulation has the potential to save energy and carbon when installed in an application where there is resistance to the transfer of heat provided by a heat source. This article will focus on the carbon reduction innovation within the closed-cell foam insulation market which includes spray polyurethane foam insulation and board stock, as this is the area where we saw the biggest technological advancement in the insulation industry in decades.

To understand the innovation and advancement in high performing insulations, we must dive into the evolution of the main component—blowing agent gases. The first-generation blowing agent gases used in thermal insulation were very effective and had high R-value potential. The downside of these agents was their negative environmental impact. The CFCs (chlorofluorocarbons) had an ODP (Ozone Depletion Potential) of 1 and a startling GWP (Global Warming Potential) of 8000. A GWP of 8000 is essentially 8000 times worse than the environmental impact of carbon dioxide.

Rockford Boyer, B. Arch. Sc., MBSc, BSS, is a building science leader at Elastochem Specialty Chemicals and brings over 20 years of technical knowledge in sustainable building design. Regarded as an expert in the field of building performance, Rockford works closely with architects using energy modelling technology to implement sustainable design strategies.

SUBSCRIBE TO THE DIGITAL OR PRINT ISSUE OF SABMAGAZINE FOR THE FULL VERSION OF THIS ARTICLE.

The Ken Soble Tower

EnerPHit transformation lights the way to new retrofit model

By Graeme Stewart

The project is not only the first such retrofit in North America but, at 18 storeys and more than 7500 m2, it is one of the largest EnerPHit1 certified projects in the world. In the Canadian context, it is also arguably the most successful to date in meeting the goals of the Federal government’s National Housing Strategy Repair and Renewal Fund.

The modernization of the building has reinstated 146 units of affordable seniors’ housing, while reinvigorating community spaces and outdoor gathering areas, enabling aging-in-place throughout, and barrier-free living in 20% of suites.

Background

The Ken Soble tower was originally constructed in 1967 and by the start of this project had fallen into a state of disrepair and was uninhabitable. One of the considerations at the outset of this project was whether to demolish the existing structure and build new, or to complete a retrofit and restore the building to a serviceable condition, consistent with today’s standards of durability and performance.

Ultimately, the team decided to retrofit which extended the life of the existing building’s cast-in-place concrete frame and part of the existing masonry envelope. The environmental impact and embodied carbon of the original construction were not wasted, nor unnecessarily duplicated in a new building. Through the Passive House level retrofit, the ongoing operational carbon emissions were drastically reduced and will support an extended service life.

Retrofit Strategies

Operational carbon reductions are achieved using a high-performance envelope, with nearly twice the insulation value required by Code, drastically reducing heating and cooling demand. The envelope upgrades include R-38 effective over cladding, passive-house certified windows and air sealing details to achieve 0.6ACH @50Pa airtightness.

Project Credits

- Owner/developer City Housing Hamilton

- Architect ERA Architects

- General Contractor PCL Constructors

- Landscape Architect ERA Architects

- Electrical Engineer Nemetz & Associates

- Mechanical engineer Reinbold Engineering

- Structural Engineer Entuitive Corp

- Commissioning Agent CFMS West Consulting Inc

- Passive House Consultant JMV Consulting

- Passive House Certifier Herz & Lang Gmt

- Building Envelope Consultant Entuitive Corp

- Photos Doublespace Photography

The renovated tower offers a built example to improve dramatically the performance of the thousands of similar apartments across North America. The AlphaGuard™ liquid-applied roofing system by Tremco Roofing helps to maintain the integrity of the building envelope.

The finished façade with new Juliette balconies. EJOT® CROSSFIX® stainless steel thermal clip brackets in the facade system help to maintain thermal performance.

Graeme Stewart is a principal at ERA Architects.

SUBSCRIBE TO THE DIGITAL OR PRINT ISSUE OF SABMAGAZINE FOR THE FULL VERSION OF THIS ARTICLE.

Sponsored content: Building the future of nuclear through responsible waste disposal

Plans have been laid for the construction of a highly engineered radioactive waste disposal facility in Chalk River, Ontario, Canada. The facility is being proposed as a permanent and modern technological solution to an environmental issue that goes back almost a century.

Today, Canadian Nuclear Laboratories (CNL) is seeking the support of the industry and its supply chain to move this project forward and advance the future of waste disposal in Canada.

Canada’s storied Chalk River Laboratories (pictured right) was established in 1944 on the Ottawa River, about 180 km (114 miles) from the City of Ottawa. An adjacent community, the Town of Deep River, was developed to support the site and remains home to generations of employees. The site is located on the traditional and unceded territory of the Algonquin Nation.

CNL is once again using leading-edge technology to put forward a long-term environmental solution. Taking guidance from domestic and international experience, CNL has proposed an engineered containment mound – the Near Surface Disposal Facility, or NSDF – as the solution for low-level radioactive waste at Chalk River Labs.

Read the case study.

Interview with Andrew Peel of Peel Passive House Consulting

Founder & Managing Principal of Peel Passive House Consulting, a Passive House Certifier, and a Certified Passive House Consultant & Trainer, Andrew Peel is one of the foremost experts on Passive House design and construction in Canada.

1. How has Passive House grown in Canada in the past five years

The growth has been exponential, especially in large affordable housing projects. The scale of projects (e.g. 40+ storey towers) was unimaginable five years ago and has eclipsed the scale of projects in Europe. Commercial Developers, including Private Equity firms, are committing to Passive House in response to changing market needs and drivers. It is thanks to the pioneers willing to take risks when others were not and the advocacy organizations that the Passive House Standard has experienced this growth.

2. What are the main obstacles to further growth?

In my experience, these challenges are:

- Eliminating the perceived risk (i.e. high additional cost) of building and certifying to the Passive House Standard.

- Developing more locally made Passive House Heat/Energy Recovery Ventilation systems and cold climate-rated fenestration products.

- Convincing appraisers to recognize the additional asset value that Passive House certification provides.

3. What are the essential first steps to getting a Passive House project off the ground?

The first step is to build the right team. This includes the Passive House Certifier, whose input at the early stages can help set the project on the right (i.e. cost effective) path. The client must commit to Passive House Certification and all key project team members must be committed to this goal. Passive House experience is not crucial. We’ve taken novice teams from start to finish to deliver Passive House buildings within budget. With the right attitude and proper training, anyone can succeed.

The second step is to optimize the high-level design consistent with Passive House principles. This seems like an obvious thing, yet it is overlooked on many projects. This often stems from not involving the Passive House Consultant from the beginning.

4. Is it realistic to apply Passive House construction to renovations?

Not only is it realistic, it is happening today. Two leading edge projects, the Raymond Desmarais Manor in Windsor, ON and the Ken Sobel Tower in Hamilton, ON are demonstrating that it can be done cost effectively on large towers. Both projects are committed to EnerPHit certification, the retrofit version of the Passive House Building standard.

5. Once a project has achieved Passive House certification is there anything the building owner must do to maintain the certification?

There is nothing required to maintain certification. However, to ensure the predicted performance is achieved perpetually, the occupants should be educated on how best to interact with the building and systems and regular maintenance per manufacturers’ instructions should be completed. Projects that fail to provide adequate occupant education have seen poorer building performance.

SUBSCRIBE TO THE DIGITAL OR PRINT ISSUE OF SABMAGAZINE FOR THE FULL VERSION OF THIS ARTICLE.

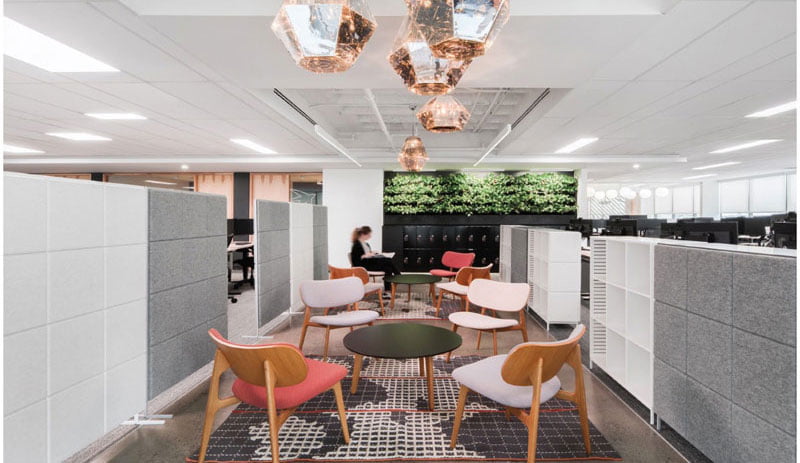

BNP PARIBAS OFFICE INTERIOR – Montreal, QC

Interior Design Award

Provencher_Roy

Jury Comment: At a time when the nature of work is in flux, the transformation of six floors of rigorously repetitious 1970s office space into a dynamic, flexible and inspiring workplace provides cause for optimism. The open, collaborative spaces and non-specific perimeter workstations flow through all levels, encouraging mobility and personal choice of working and relaxing environments throughout the day. Sit/stand desks, lighting programmed to support natural circadian rhythms, and 20 living walls contribute further to psychological and physiological wellbeing.

The first project in Canada to be certified under Version 2 of the WELL Building Standard, the new headquarters for BNP Paribas , the French international banking group, exemplifies current best practice in employee-centred office design. To alleviate overcrowding and bring its 140 staff under one roof, the company chose to relocate and refit 140,000 sq.ft. of space spread over six floors of an existing 1970s office building.

From the outset, the aim was to achieve WELL Building certification and to create a dynamic work environment that would promote social interaction and collaboration as well as the health and comfort of occupants. The challenge was to meet the client’s desire for a fluid, flexible, non-Cartesian layout of space within the physical constraints of the existing structure, which included working with the two feet by four feet ceiling grid.

This led to the development of a workplace where the main open spaces are divided into several zones alternating those intended for work, collaboration and rest. Work areas are not assigned; employees can settle wherever they want in the building, or even telecommute. The workstations are arranged at the perimeter, so employees benefit from maximum natural light. Common spaces are located at the core of the building and include glazed meeting rooms, changing rooms, and sanitary facilities.

To energize the occupied spaces, the strategy was to create what the design team refers to as “organized chaos” through the choice and arrangement of lighting and office furniture. Artificial lighting integrates a variety of high-performance luminaires, adapted to the functions of the different areas with dynamism in mind. As required by WELL, the lighting is designed not to disrupt the occupants‘ circadian rhythms.

The office furniture system includes a spine that integrates all the wiring required. Workstations can be moved along this spine in either direction to modify the space and employees can alternate between sitting and standing positions. Low VOC materials minimize airborne pollutants and 20 living walls help purify the air while enhancing the human biophilic response.

PROJECT CREDITS

- Architect Provencher_Roy

- Owner/Developer GWL (Great West Life)

- General Contractor Avicor Construction

- Electrical Engineer Planifitech

- Other Make Space Work, Ameublement intérieur

- Senoir Design Haworth

- Photos David Boyer

SUBSCRIBE TO THE DIGITAL OR PRINT ISSUE OF SABMAGAZINE FOR THE FULL VERSION OF THIS ARTICLE.

Prefabrication and Modular Construction

The thermal performance of off-site prefabricated buildings and building enclosure systems

The thermal performance of off-site prefabricated buildings and building enclosure systems

By Val Sylaj and Brian J Hall

As designers and owners are becoming more aware of the environmental impacts of the construction industry, including the types of materials used, more stringent requirements are being imposed by specifiers, and national codes and standards.

This article provides some insights on the important measures of prefabrication and panelized systems on the thermal performance of buildings, the energy consumption, and the financial impacts to the investors.

A recent report from Dodge Data and Analytics published in 2020 shows a significant interest by the construction industry in prefabrication and modular construction mainly because of the improved productivity, reduced timeline, and cost, better sustainability performance, etc.

https://www.construction.com/toolkit/reports/prefabrication-modular-construction-2020

An earlier report from Dodge Data and Analytics published in 2011 had also highlighted the following as the underlying drivers and benefits of prefabrication and modular construction: (1) Improved productivity and quality are key benefits in its usage, (2) Positive impacts on budget and schedule performance are widely experienced, and (3) Construction sites are ‘greener’ due to less waste being generated, and safer due to working with structure assemblies and modules produced offsite.

Although major advances have been made in both prefabrication and modular construction since the 2011 report, many of the above mentioned factors are still consistent with the findings of the latest report from 2020.

What is Prefabrication and Modular Construction?

With rapid population growth, the construction industry is always challenged to adapt its technologies based on the market demand such as the need for taller buildings, reduced onsite construction times, enhanced building performance, etc. Prefabrication and modular construction are certainly a solution to most, if not all, of these demands.

Prefabrication is a construction method that involves fabricating and assembling building components offsite. It can refer to both flat elements (often known as prefabricated panelized systems), or to modular volumetric units that typically include complete spaces of a building such as an apartment unit, hotel room, jail cell, etc. In either case, prefabrication construction also provides innovative solutions in buildings where the entire building envelope can be fabricated offsite using prefabricated building components.

In addition to the need for accelerated building construction technology and consistency in quality, prefabrication and modular construction are also being considered to address concerns with site-specific skilled labour shortages. With prefabrication that is completely performed at an offsite facility, plant workers can be trained to perform specific skilled trades such as electrical and plumbing that form part of the finished element or room.

Standard building construction practices require individual building components or materials to be delivered to a job site, stored and then placed or installed by labourers from multiple trades. This requires significant on-site space as well as time for setup and construction. Another very time-consuming on-site operation process is the exterior finish of the final building façade.

Conversely, off-site prefabricated components are delivered ‘just-in-time’ and installed by a smaller crew of skilled installers/erectors, directly from the truck onto the building, with the façade and architectural finishes already complete.

It is clear that prefabrication is an ideal construction technology with minimal site disturbance and less labour required compared to traditional construction. Another important factor is improved safety, mainly because the work is done at ground level at a prefabrication facility, instead of working at elevated heights which is common with traditional construction. Further, the safety measures such as physical distancing during a pandemic can be easily implemented with very minimal or no effect on production.

SUBSCRIBE TO THE DIGITAL OR PRINT ISSUE OF SABMAGAZINE FOR THE FULL VERSION OF THIS ARTICLE.

Design practice: Rethinking Multi-Unit Residential Design

Optimizing flexibility, affordability and construction efficiency

Optimizing flexibility, affordability and construction efficiency

By Michelle Xuereb, Dev Mehta, Adryanne Quenneville and Tiffany Wong of BDP Quadrangle

The world is in a period of increased urbanization. In 2018 the United Nations estimated that by 2050 68% of the global population will be living in an urban area. Urban population growth has driven up land value and the costs associated with residential building construction. For most, living in an urban area means residing in a multi-unit residential building (MURB).

As the costs related to urban residential development have increased, the average unit size has decreased. For example, a typical two-bedroom-plus-den unit in one of Toronto’s older stock of residential buildings is usually around 1,000 square feet. Current residential developments fit the same program into roughly 750 square feet.

This squeezing of the floor plans, however, has reached its breaking point. Residential units can only be tightened so much without sacrificing the quality and functionality of the space. When every room is competing for floor area, designers need to get creative.

In March, BDP Quadrangle held a studio-wide ‘Shrinking Spaces Charrette’ to come up with innovative solutions for small units. We took a typical residential unit apart – examining every inch of space from the master bedroom to the pantry shelf – to find creative new ways of maximizing square footage within a limited space.

The future MURB unit does away with fixed rooms with set programs. Isolating in response to the pandemic has prompted all of us to find more flexibility in our living spaces, and also to question how MURB design can go further to support a sense of community and foster interaction with others while still maintaining privacy and a safe distance if required.

This pandemic experience has equipped us with a direct and immediate understanding of the specific desires for an improved at-home wellness experience – such as a need for both togetherness and separation from other family members; having a place to stow away a computer at the end of the day; the possibility to grow vegetables on a balcony; and the benefit of socializing with neighbours. We identified a need for more resilient, sustainable, flexible, and healthy spaces – all within a small footprint in order to maintain an affordable unit.

We began rethinking MURB units by asking: what would happen if we reduced or eliminated set programs? In order to optimize flexibility, we propose blurring the lines between rooms, rather than delineating them with demising walls.

To accommodate this, the building is designed with a structural column grid instead of shear walls, as is typical of Toronto construction. This structural system also uses less concrete – thereby reducing the building’s carbon footprint. For other elements that are typically fixed in place, such as the plumbing stacks and mechanical shafts, we arranged them in a manner that allows for an open plan: the kitchen, bathrooms, and laundry closets are consolidated on the perimeter of the unit. These shifts allow for a more flexible floor plan.