DIY tiny houses move to the next level as an architecture student introduces digital design and fabrication into the mix.

By Mike Reynolds

Ben Hayward is a Carleton University Architecture grad student who has broken the typical mould of tiny houses, and designed something that in our opinion takes a big step closer to achieving one of the main goals of the tiny house movement; namely, being ‘green'.

It seems somewhat contradictory for an environmentally conscious person to be dragging a home with mediocre performance behind a massive gas-guzzling truck. Small is good, mobile not so much; but the Achilles Heel of tiny houses is balancing interior living space with a maximum highway width of 8.5 feet. That almost always leads to weak thermal performance as well as the use of spray polyethylene foam for its higher R value per inch. Doing that means you also drag around a high ecological footprint in the form of significant greenhouse gas emissions due to the blowing agents found in almost all brands of spray foam.

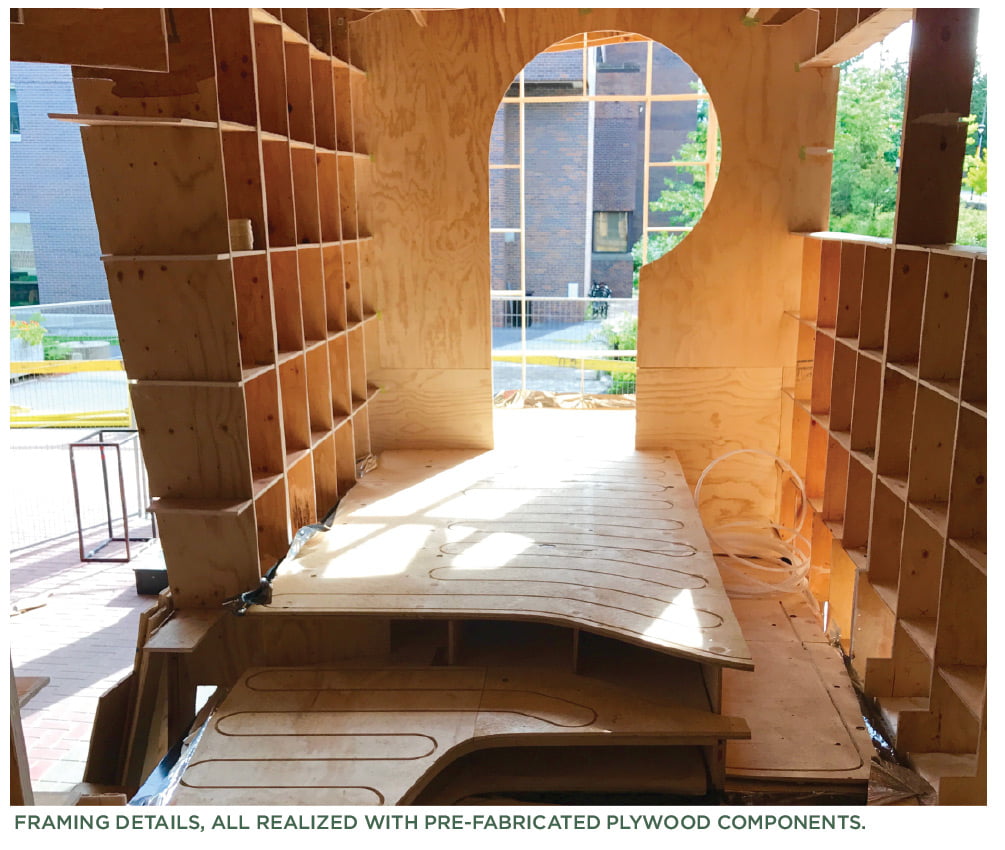

The wall structure of Ben Hayward's 180 square foot tiny house is his own grid-like design of plywood, and is insulated with mineral wool. The wall thickness and level of insulation varies slightly, with the weakest point being R48, which is about double that of your typical new home under construction.

Digital design

Having done a 3D computer model of the building shape made it possible to use the CNC machine at Carleton University [computer numerical control], an automated mill that cut the plywood wall components to an accuracy of within 1 mm, and allowed pieces to be friction fit during assembly.

“With such a fine tolerance of accuracy, we were able to achieve complex curvature that would be too complicated to do in any other way”, says Hayward, who goes on to compare the assembly to doing “a big 3D puzzle”.

Mike Reynolds is a former home builder, a LEED for Homes Green Rater and the editor of Ecohome.net, the affiliate web site of ecoHouse Canada.