Visualizing the pathway to low energy buildings

Visualizing the pathway to low energy buildings

Thermally efficient building envelopes have long been recognized as a necessity for low energy buildings in heating dominated climates. Low energy buildings are not only a goal for buildings built to green rating systems, but are also a stated long-term developmental objective of energy standards that are applicable to all large buildings. Building envelope thermal performance is an increasingly essential consideration as industry is tasked with designing and constructing buildings that consume less energy. This article provides an overview of the resources that are now available to practitioners to help design building envelopes that can be aligned with specific project performance objectives and construction realities.

By Patrick Roppel

Take approved SABMag continuing education courses for LEED AP credential maintenance. Read this article and take the quiz at: WWW.SABMAGAZINE-EDUCATION.INFO to receive 1 Core Learning Unit

Building envelope thermal performance is greatly affected by thermal bridging, or localized areas of increased heat flow through walls and roofs. Mitigating the impact of thermal bridging is not only necessary to reduce energy consumption but is also an important consideration for minimizing the risk of condensation on cold surfaces and for maintaining occupant comfort.

Most designers of large buildings have moved beyond mistakenly using nominal R-values of assembly cross sections in load and energy calculations. They understand that it’s the “effective” R-value that counts; the thermal resistance through an assembly that includes the effects of thermal bridging. The present day scenario is more likely to see a design team focused on hard targets for the “effective” R-value or thermal transmittance [U-value] of wall and glazing assemblies, but overlooking the impact of thermal bridging at the interface between building envelope components [interface detail]. Examples of thermal bridging at interface details include intermediate floor slabs, interfaces between windows and walls, parapets, and intersections to interior walls.

Research has shown that the impact of thermal bridging at interface details is significant to the building envelope thermal performance, energy consumption in heating dominated climates, and the realization of low energy buildings. Unmitigated thermal bridging can undermine long-standing strategies to improve building envelope thermal performance, such as minimizing glazing area, maximizing glazing performance, increasing air-tightness, and adding more insulation. The importance of mitigating the impact of thermal bridging at interface details is ever more important as designs increasingly rely on higher “effective” R-values to meet energy related targets.

In the past, there were good and logical reasons for design teams ignoring the impact of thermal bridging at interface details, which included:

1. Prevailing methods to assess the impact of thermal bridging were complicated

2. A lack of generic data to assess thermal bridging without project specific analysis

3. The impact of thermal bridging at interface details, especially components with small areas, was assumed to be low

4. Energy standards and codes typically did not effectively address thermal bridges at interface details.

ASHRAE 1365-RP “Thermal Performance of Building Envelope Details for Mid- and High-Rise Buildings”, put forward procedures and data that helped address the first three points. The 1365-RP calculation procedures are similar to the methods employed by Passive House, a standard that requires project specific heat loss calculations to certify buildings. 1365-RP started a market transformation to better evaluate building performance but only scratched the surface in terms of identifying how to mitigate thermal bridging in design and did not address the impact on energy consumption in buildings.

Enter the new Building Envelope Thermal Bridging [BETB] Guide

The BETB Guide is a valuable reference tool that contains essential information for evaluating building envelope thermal performance, including easy-to-use methods for understanding, accurately calculating and mitigating thermal bridging, along with an extensive catalogue of thermal performance data. It expands significantly on previous work, and identifies opportunities to incentivize improving industry practice. Emerging technologies and construction practices that offer substantial improvements to current construction practice are explored. The BETB Guide systematically addresses the first three points above and helps with work that is currently underway to better address thermal bridging in energy codes and standards.

Regardless of what designers are compelled to consider for compliance with energy standards, thermal bridging should be an essential consideration for designing sustainable buildings. There is no longer justification to ignore thermal bridging at interface details because we know the impact is significant and we have the tools to access how to best deliver more efficient building envelopes.

Take a holistic perspective to thermal bridging

Taking a holistic perspective to thermal bridging means that design teams put less emphasis on meeting hard targets for assemblies that are evaluated in parallel and focus more attention on delivering building envelopes where performance is measured as connected components. The following discussion puts this grandiose concept into context.

Assembly “Effective” R-values, or Assembly U-values, consider only the impact of repetitive thermal bridges, such as studs, girts, joists, and ties, that are part of an assembly. These are the values that are found in the assembly U-factor tables in Appendix A of ASHRAE 90.1. Design teams can easily get caught up with trying to achieve continuous insulation, specifying the most efficient assembly, or adding more insulation to comply with maximum assembly U-values. However, in the process, they overlook thermal bridging at the interface between assemblies and building envelope components. The issue is that a design team can be laser focused on optimizing the assembly U-values to the third decimal point but not recognize that potentially as high as four times the heat flow is being overlooked due to thermal bridging at interface details.

For a low energy building, where energy efficiency measures are applied across the board, the difference in energy intensity between an idealized analysis where only assembly U-values are assumed to be important and reality of unmitigated thermal bridging is in the range of 10 to 20% of total energy use for heating dominated climates. The consequence of such a flawed design process is not only that buildings may be constructed that do not realize their energy-use targets, but also can result in inefficient operation of HVAC systems, poor occupant comfort, and higher than necessary embodied energy. In other words, missing the mark for many of the goals of sustainable buildings.

Calculating U-Values using the BETB Guide is not rocket science

The data contained in the BETB Guide was determined using the same 3D finite element heat transfer analysis software that was relied upon to design and test the Curiosity Rover that successfully landed on Mars in 2012 and continues to explore the red planet. Hopefully this provides some confidence towards the accuracy of the analysis that supported the creation of the BETB Guide. However, the comparisons to rocket science and the complexity of the latest Mars mission end there.

Although the tools, expertise and software were available to provide solutions for every variable down to multiple decimal places for the BETB Guide, it was recognized that industry needed practical engineering solutions rather than scientific research. Accordingly, you don’t need to be a rocket scientist to understand the BETB Guide and apply the information in practice. Greg McCall from the City of Vancouver puts this into perspective by saying, “It used to take me two whole weeks to calculate the performance of a building envelope, with plans all over the floor, colour crayons everywhere. Fast forward to today and practitioners now have access to the latest in modern technology to calculate energy performance in far less time and with far greater accuracy.”

Here are some suggestions to help you navigate the BETB Guide. Start with Part 1, which is the user’s guide for calculating the impact of thermal bridges. There are step-by-step examples to show how to do the calculations, guidance for quantity takeoffs, guidance on additional sources of information, and how to interpret the data.

Sure, there are a couple of math equations in there, but the math is not any more complicated than estimating costs. You take the square foot heat loss for an assembly [analogy to square foot costs for assemblies] and add the incremental heat loss for interface details [analogy to the of extra detail work] to get the total heat loss. You can even download spreadsheets where all the calculations are already set-up.

There are visual summaries at the beginning of Appendix B that are useful for quick scans to help identify default values for transmittances. This information is further distilled into four tables in Part 1 that outline performance categories per type of interface detail and identification of corresponding default values. These tables are useful for team members that don’t appreciate the subtle difference between various architectural details or are reluctant to interpolate because the building envelope is not their expertise, but are tasked with calculating U-values for load calculations or energy modelling. A sample table for floor and balcony interface details follows on the next page.

The impact depends on the quantity and quality of the detail

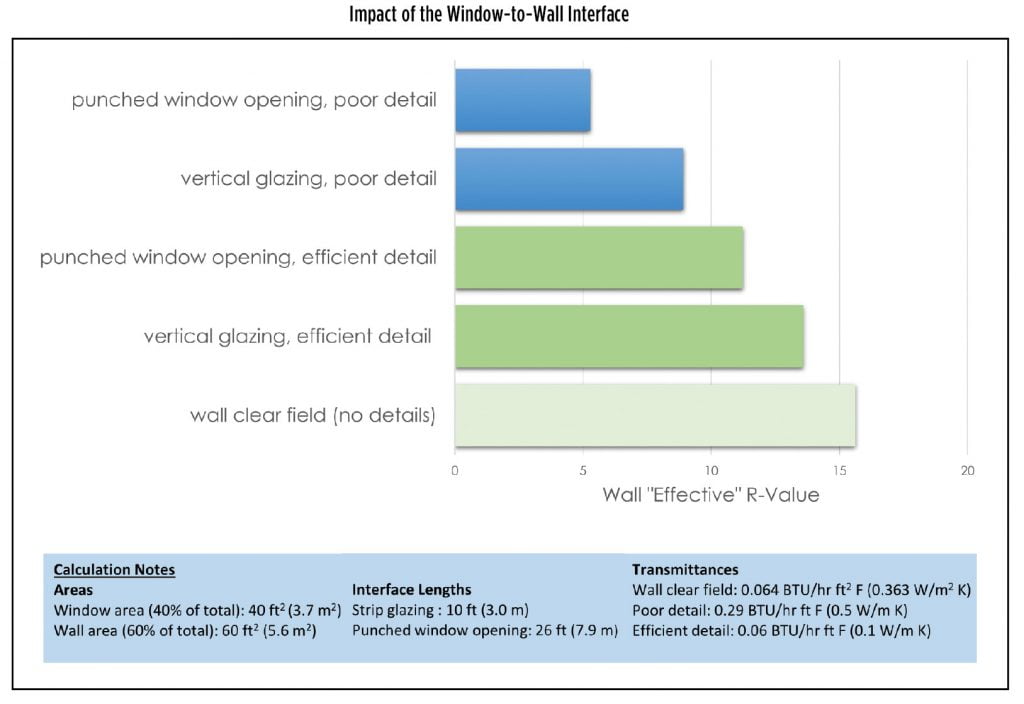

Nothing exemplifies this concept better than exploring the impact of window-to-wall interfaces. The performance of windows and walls are typically evaluated separately. For good reason, windows affect energy consumption in more ways than opaque walls because of daylight and solar heat gain. Windows also typically have higher assembly U-values than wall assemblies.

Conventional wisdom for designing energy efficient envelopes, when thinking in parallel, is geared towards minimizing window area, selecting energy efficient glazing, and providing well-insulated walls. However, thermal bridging is inherently introduced when we place windows into walls, often not enough attention is paid to this interface, and the impact on the thermal performance can be significant.

A fun fact about window to wall interfaces is that many small windows in punched openings can have a surprisingly high perimeter length; actually measured by the mile for large buildings. A little extra heat loss due to less than perfect detailing can translate into a big impact. This is why this interface is so important. Windows in punched openings can be a lot less energy efficient than horizontal strip glazing or floor to ceiling glazing for the same areas and assembly performances. This is because the window to wall interface length for punched openings is often larger than for strip glazing, and thermally inefficient details are amplified by the larger quantities. The chart below right illustrates this concept for two interface lengths and quality of details.

The window-to-wall interface has implications beyond energy efficiency. Windows that are connected to a steel or concrete building structure or connected to other components not often evaluated, such as deflection headers, can cool down the window frame.

Cooler interior surface temperatures of glazing is an important consideration for evaluating condensation risk and occupant comfort in heating climates. Both these factors also have further energy implications because occupants often crack open windows and/or crank up the heat to deal with condensation on windows or uncomfortable conditions. For these reasons, the window-to-wall interface, measured as connected components, warrants more attention when designing sustainable buildings.

How to focus on what is important from a whole building perspective

The building envelope thermal bridging analysis [BETA] method presented in the BETB Guide allows designers to focus on the details that matter the most to the overall building envelope thermal performance. The contribution that each detail has on the overall heat flow can be isolated. Therefore, designers can assess how to best mitigate the impact of thermal bridging by several approaches:

1. Avoid thermal bridges, such as not bringing concrete columns through the building envelope

2. Provide more effective insulation, such as aligning glazing with the wall insulation

3. Minimize the quantity of interfaces, such as not overdoing articulating architecture

4. Introduce technology, such as structural thermal breaks

A default for sustainable large buildings should not always be lofty targets, such as R-30 walls, if costs are a consideration. It’s a shame when limited resources are spent where they don’t have the “biggest bang for your client’s buck”.

Or even worse – there is no way to realize the calculated energy savings in reality because an important factor, such as thermal bridging, was not thoroughly considered.

The BETB Guide provides the means to consider thermal bridging thoroughly in design, but only deals with one variable for the myriad of variables that impact building energy consumption. The building envelope only affects a piece of the energy pie. Low energy buildings require a multitude of energy conservation measures to be incorporated into the building design.

Whole building energy analysis is required to evaluate the optimal energy and cost-effective building design. However, many design teams or energy modellers use whole building energy analysis for verification rather than as a tool for aiding design. The verification approach misses the fact that there are diminishing energy saving returns, energy performance is dependent on interrelated variables, and there are many roads that lead to the same performance.

A multi-variable visualization technique is a very useful design tool to narrow in on what matters; resulting in less time spent trying to meet static targets for the building envelope that might be unrealistic, not cost effective, and/or set too high. High level visualization techniques combined with detailed and realistic U-value calculations is the future of better low energy and sustainable building design.

Patrick Roppel is an engineer with Morrison Hershfield Ltd. He was the project and technical manager for both ASHRAE 1365-RP “Thermal Performance of Building Envelope Details for Mid- and High-Rise Buildings” [2011] and the Building Envelope Thermal Bridging Guide [2014], and serves on the Thermal Bridging Task Group for ASHRAE standard 90.1.